Introduction:

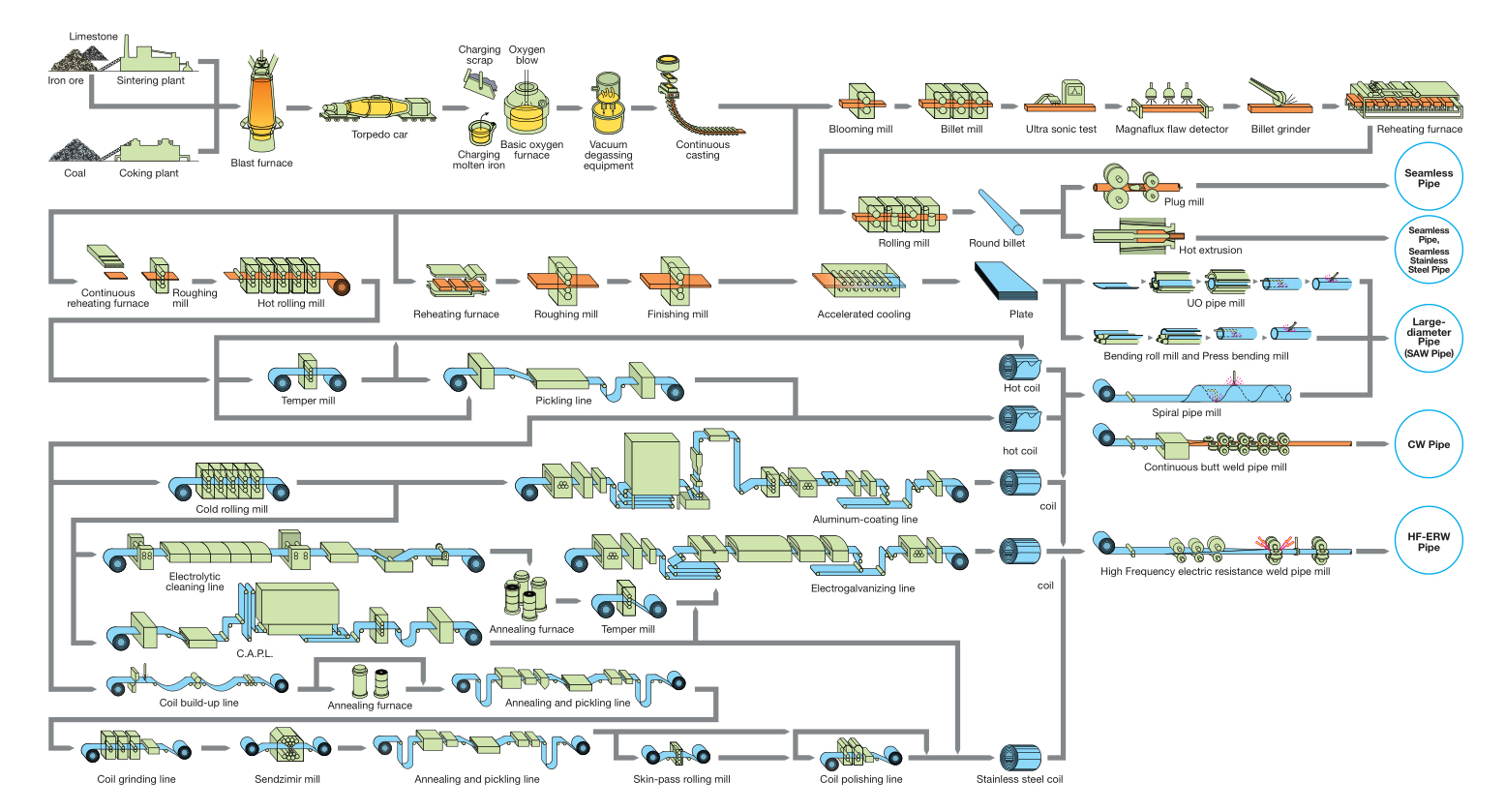

Type de tuyau: Tuyau de ligne, Tuyau de ligne Api, Tuyau de ligne sans soudure, Tuyau de ligne en acier au carbone

Application: Pour le transport dans des industries de pétrole et de gaz naturel

PRODUIT: LIGNE TUYAU, LIGNE TUYAU d'api, LIGNE SANS SOUDURE TUYAU, LIGNE TUYAU D'ACIER AU CARBONE

TAILLE:

OD: 73-630MM

POIDS: 6-35MM

LONGUEUR: 5.8/6/11.8/12M

TUYAU STANDARD:API 5L PSL1/PSL2 G R.A,G R.B,X42,X46,X52,X56,X60,X65,X70

Api 5L PSL1/PSL2 L210,L245,L290,L320,L360,L390,L415,L450,L485

Revêtement

Fbe - Awwa C210, Awwa213, As/N2s 3862, Can/Csa Z245.20 et etc.

3lpe - Din30670, Nfa49-710, Ips-G-Tp-335 Iso21809 et etc.

3lpp - Din30678, Gs-Gr-Cor 221, Iso21809 et etc.

Application

· Pétrole et gazoducs

· Canalisations d'eau et d'eaux d'égout

· Pipelines de boue minérale

Avantages de la ligne tuyau d'api 5l

Meilleur pour les systèmes de transport dans les industries du gaz naturel et du pétrole.

Approprié au gaz, à l'eau, et au pétrole de transport.

Contraintes mécaniques élevées résistantes.

Résistant à la haute pression et à la température.

English

English Español

Español Français

Français بالعربية

بالعربية