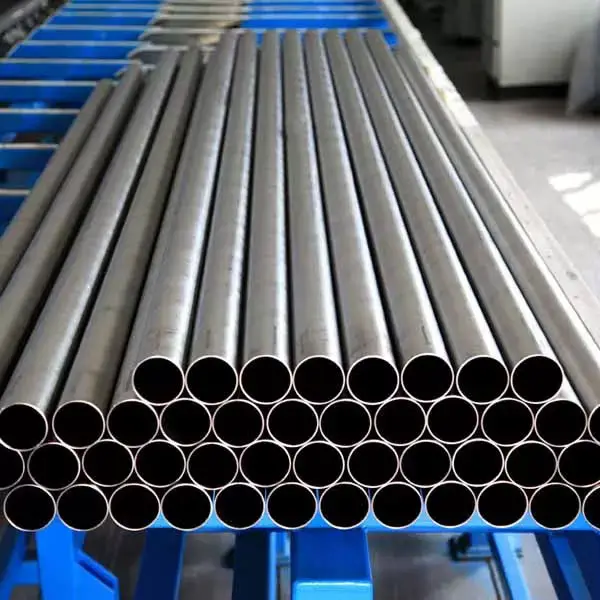

Nom du produit: Tuyau en alliage de titane, tube en titane sans soudure, tube sans soudure en titane Astm, tube en titane

Diamètre extérieur: 6-2500mm, (3/8 "-100")

Épaisseur: 0.3-150mm,(Sch10-Xxs)

Longueur: 2000mm, 2500mm, 3000mm, 5800mm, 6000mm,12000mm, etc

Norme: Astm/Asme B338, B337, B861,B862,Jis H4631 Jis H4630 Aisi,Jis, Din,,En

Surface :Ba,2b,No.1,No.4,4k,Hl,8k

Matériel: Titane Gr1, Gr2, Gr3, Gr5, Gr7, Gr9 Gr12

Certification:Iso, Sgs,Bv

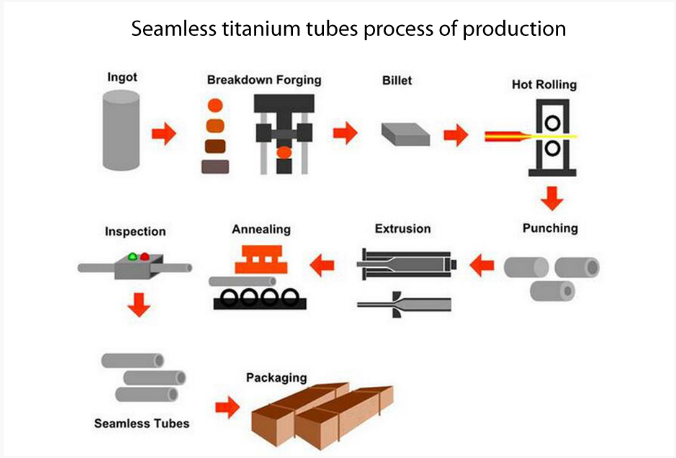

Technique: Tube sans couture étiré à froid/tuyau soudé

Bord: Bord de fente de bord de moulin

Application: Il est très utilisé dans l'industrie à hautes températures et électrique, les dispositifs médicaux, la construction, la chimie, l'industrie alimentaire, l'agriculture, et les composants de bateau.

Il s'applique également à l'emballage de nourriture et de boisson, aux approvisionnements de cuisine, aux trains, aux avions, aux bandes de conveyeur, aux véhicules, aux boulons, aux écrous, aux ressorts, et à la maille etc. d'écran.

English

English Español

Español Français

Français بالعربية

بالعربية