- الوصف

- مواصفة

- ستاندرد

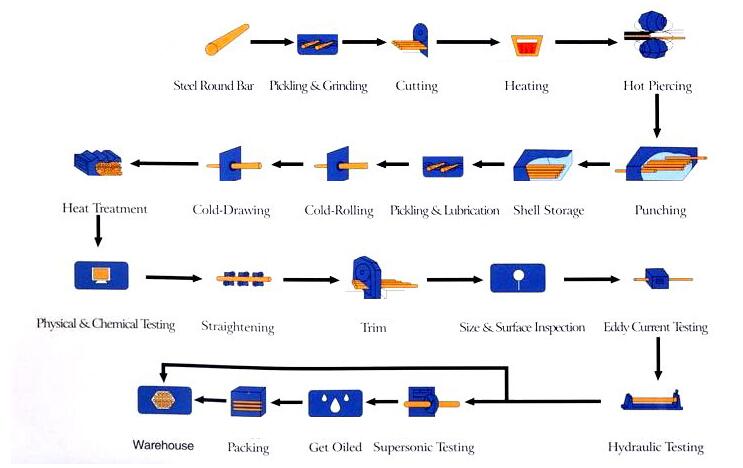

- عملية

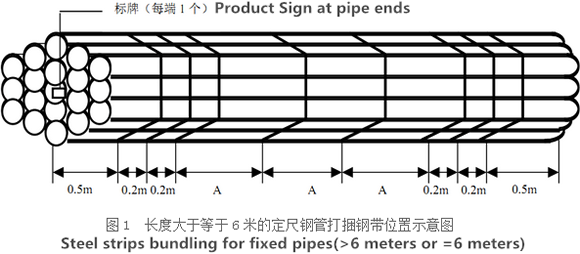

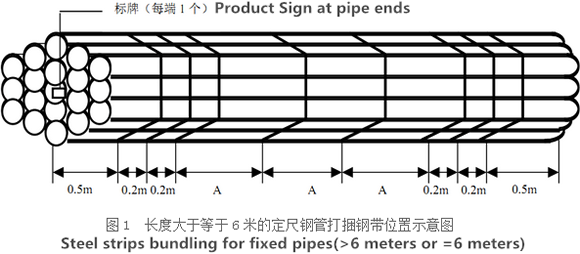

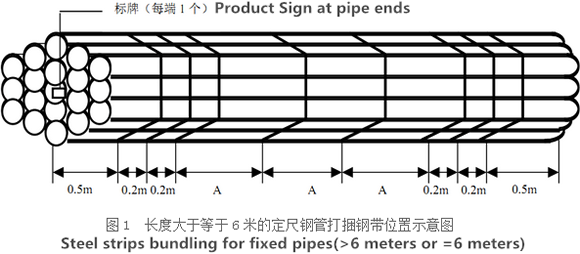

- التعبئة

الوصف

اسم: Astm A335 سبائك الصلب الأنابيب

القطر: 16-1016

السماكة: 2-120

درجة الفولاذ: P1 P2 P5 P9 P11 P12 P22

السطح: مزيت ، مطلية باللون الأسود لمنع الصدأ

ملفات التطبيق: المراجل الصناعية ، محطات الطاقة ، محطات الطاقة النووية

كيفية تحديد أنابيب السبائك ؟

أنابيب السبائك أنبوبية بنسب مئوية أعلى ، من أنابيب الصلب الكربوني القياسية ، من عناصر السبائك مثل الموليبدينوم (مو) ، الكروم (كر) ، النيكل ، إلخ. في الواقع ، يغطي Astm A335 أنابيب فولاذية منخفضة السبائك ، أي الأنابيب التي تحتوي على كمية إجمالية من عناصر السبائك أقل من 5 ٪. تؤدي إضافة نسب مئوية أعلى من عناصر السبائك (على سبيل المثال النيكل والكروم) إلى تحويل الفولاذ إلى سبائك أعلى ، مثل الفولاذ المقاوم للصدأ ، والدوبلكس ، وما يصل إلى مواد فائقة السبائك مثل Inconel ، و Hastelloy ، و Monel ، وما إلى ذلك.

تستخدم أنابيب الفولاذ السبائكي في صناعة الطاقة لدرجات الحرارة العالية وخدمة درجات الحرارة المنخفضة جدًا (المبردة) ، أو التطبيقات ذات الضغوط العالية جدًا.

أنابيب فولاذية من سبائك Astm A335 تناسب تجهيزات Buttweld من سلسلة Astm A234 Wpx (Wp5 ، Wp9 ، Wp91) و A182 Fx تركيبات وشفاه مزورة (A182 F5 ، F9 ، F11 ، F22 ، F91). جميع هذه المواد لها خصائص كيميائية وميكانيكية مماثلة ويمكن ضمها أو لحامها.

أنبوب Astm A335 (Asme S/A335 ، Chorme-Moly) هو أنبوب فولاذية من سبائك الحديد غير ملحومة لخدمة درجات الحرارة العالية. يجب أن يكون الأنبوب المطلوب وفقًا لهذه المواصفات مناسبًا للثني ، والتشفيه (الرجم) ، وعمليات التشكيل المماثلة ، ولحام الانصهار. يشار إليها أحيانًا باسم "P Grade" ، أنبوب تشومي مولي شائع في درجات P P5 و P9 و P11 و P22 و p9.1 الاستخدام الأكثر شيوعًا للصفوف P11 و P22 و P91 هو في صناعة الطاقة ومصانع الكيماويات البتروكيميائية ، وتستخدم الدرجات P5 و P9 بشكل شائع في المصافي

غالبًا ما يطلق على A335 أنبوب مولي من الكروم بسبب التركيب الكيميائي للموليبدينوم (مو) والكروم (كر). يزيد الموليبدينوم من قوة الفولاذ وكذلك الحد المرن ، ومقاومة التآكل ، وخصائص التأثير ، والقدرة على التصلب. يزيد المولي من مقاومة التليين ، ويقيد نمو الحبوب ويجعل فولاذ الكروم أقل عرضة للتقشر. مولي هو المضاف الفردي الأكثر فعالية الذي يزيد من قوة الزحف بدرجة حرارة عالية. كما أنه يعزز مقاومة التآكل من الفولاذ ، ويمنع تأليب. الكروم (أو الكروم) هو المكون الأساسي للفولاذ المقاوم للصدأ. أي فولاذ يحتوي على 12% أو أكثر من الكروم يعتبر من الفولاذ المقاوم للصدأ.

أنابيب غير ملحومة من سبائك الصلب (معتمدة من Ibr)

أنابيب سبائك الصلب غير الملحومة (Ibr) التي نقدمها مصنوعة من سبائك الصلب وتتميز بخصائص أداء استثنائية. تم تطوير هذه التطبيقات للتطبيقات المتعلقة بالطاقة التي تنطوي على حفر النفط والغاز وبالتالي تتعرض للضغوط في أجزاء الماكينة. علاوة على ذلك ، تستخدم الأنابيب الفولاذية المصنوعة من السبائك أيضًا في المناطق المحلية أو المهنية أو الصناعية. أنابيب سبائك الصلب غير الملحومة (Asme Sa335 درجة P5)

أنابيب سبائك الصلب غير الملحومة (Asme Sa335 Grade P5) التي نقدمها متاحة في Asme Sa335 وكذلك P1 ، P5 ، P9 ، P11 ، P12 ، P91 الدرجات. تكمن خبرتنا في تقديم هذه التقارير بأحجام وجداول مختلفة ، مع تقارير Ibr وأحدث إصدار Nace Mr 0175.

أنابيب/أنابيب غير ملحومة من سبائك الصلب Asme (Sa335 درجة P9)

تستخدم الأنابيب/الأنابيب غير الملحومة من سبائك الصلب Asme (Sa335 درجة P9) المصنعة والموردة والمصدرة من قبلنا في العديد من التطبيقات الصناعية. تخصصنا في تقديم سبائك الفولاذ الهندسية الدقيقة يسمح لنا بتقديمها لمختلف التطبيقات الهندسية في درجات مختلفة مثل J Gr. P1 و P5 و P9 و P11 و P12 و P22 و P91 و Astm وغيرها. المواصفات الأخرى تشمل:

أنابيب سبائك الصلب (Astm A335 P11)

الأنابيب الفولاذية المصنوعة من السبائك (Astm A335 P11) التي نقدمها لنا مصنوعة وفقًا لمعايير Ibr وتستخدم بشكل أساسي في عمليات الغلايات. نحن مصدر هذه الأنابيب غير الملحومة في نطاق أحجام متنوعة. علاوة على ذلك ، يمكننا أيضًا الحصول على هذه مخصصة وفقًا لمتطلبات أنابيب المرجل. لضمان معايير الجودة المثلى ، نحن مصدرها من الشركات المصنعة للجودة. كما نقدم للعملاء علامة خاصة بهم.

أنابيب سبائك الصلب (Astm A335 P12)

أنابيب فولاذية من السبائك (Astm A335 P12) متوفرة بمعيار Astm A335 P12 وتجد تطبيقًا في صناعات مثل البتروكيماويات والمصافي والأسمدة والمستحضرات الصيدلانية وغيرها. يمكننا الحصول على هذه الأنابيب غير الملحومة في نطاق يصل إلى 26 بوصة.

أنابيب سبيكة غير ملحومة (Astm A335 الصف P91 نيس)

الأنابيب غير الملحومة المصنوعة من السبائك (Astm A335 Grade P91 Nace) التي نقدمها لنا متوفرة في درجات Astm A335. مصنوعة وفقًا لمعايير Ibr ، تُستخدم هذه بشكل رئيسي في عمليات الغلايات. علاوة على ذلك ، تكمن خبرتنا في تقديم هذه الأنابيب في نطاق مختلف الأحجام وكذلك في المعلمات المخصصة حسب متطلبات أنابيب الغلاية. مصدرها الشركات المصنعة للجودة واعية ، كما نقدم لعملائنا خيار إضافة علامتهم الخاصة عليهم.

مواصفة

astm a335 steel pipe chemical composition:

|

material

|

c

|

si

|

mn

|

p

|

s

|

mo

|

cr

|

|

|

%

|

%

|

%

|

%

|

max

|

%

|

max

|

|

a335 grade p1

|

0.10---0.20

|

0.10---0.50

|

0.30---0.80

|

0.025

|

0.025

|

0.440.65

|

|

|

a335 grade p5

|

max 0.15

|

max 0.50

|

0.30---0.60

|

0.025

|

0.025

|

0.450.65

|

4.006.00

|

|

a335 grade p11

|

0.05---0.15

|

0.5---1.0

|

0.30---0.60

|

0.025

|

0.025

|

0.450.65

|

1.001.50

|

|

a335 grade p12

|

0.05---0.15

|

max 0.50

|

0.30---0.61

|

0.025

|

0.025

|

0.450.65

|

0.801.25

|

|

a335 grade p22

|

0.05---0.15

|

max 0.50

|

0.30---0.60

|

0.025

|

0.025

|

0.871.13

|

1.902.60

|

astm a335 steel pipe mechanical properties:

|

material

|

tensile n/mm2

|

strength min n/mm2

|

yield %min

|

|

a335 grade p1

|

min380

|

205

|

30

|

|

a335 grade p5

|

min415

|

205

|

30

|

|

a335 grade p11

|

min415

|

205

|

30

|

|

a335 grade p12

|

min415

|

205

|

30

|

|

a335 grade p22

|

min415

|

205

|

30

|

stm a335 steel pipe may be either hot finished or cold drawn with the finishing heat treatment noted below.

|

astm a335 grade

|

heat treatment type

|

normalizing temperature range f [c]

|

subcritical annealing or tempering

temperature range f [c]

|

|

p5 (b,c)

|

full or isothermal anneal

|

|

|

|

|

normalize and temper

|

-

|

1250 [675]

|

|

|

subcritical anneal (p5c only)

|

-

|

1325 - 1375 [715 - 745]

|

|

p9

|

full or isothermal anneal

|

|

|

|

|

normalize and temper

|

-

|

1250 [675]

|

|

p11

|

full or isothermal anneal

|

|

|

|

|

normalize and temper

|

-

|

1200 [650]

|

|

p22

|

full or isothermal anneal

|

|

|

|

|

normalize and temper

|

-

|

1250 [675]

|

|

p91

|

normalize and temper

|

1900-1975 [1040 - 1080]

|

1350-1470 [730 - 800]

|

|

|

quench and temper

|

1900-1975 [1040 - 1080]

|

1350-1470 [730 - 800]

|

ستاندرد

CHEMICAL COMPOSITION

The types of alloy steel covered by the ASTM A335 – ASME SA335 specification are designed with a “P” prefix, from P5 to P92. Grades P11/P22 and P91/92 are typically found in power stations, whereas grade P5 and P9 are more common for application in the petrochemical industry. Grades P9 and P91 are in the list, the more expensive.

|

ASTM A335

Low-Alloy Steel

(Grades)

|

UNS

equivalent

|

C≤

|

Mn

|

P≤

|

S≤

|

Si≤

|

Cr

|

Mo

|

|

P1

|

K11522

|

0.10~0.20

|

0.30~0.80

|

0.025

|

0.025

|

0.10~0.50

|

–

|

0.44~0.65

|

|

P2

|

K11547

|

0.10~0.20

|

0.30~0.61

|

0.025

|

0.025

|

0.10~0.30

|

0.50~0.81

|

0.44~0.65

|

|

P5

|

K41545

|

0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

4.00~6.00

|

0.44~0.65

|

|

P5b

|

K51545

|

0.15

|

0.30~0.60

|

0.025

|

0.025

|

1.00~2.00

|

4.00~6.00

|

0.44~0.65

|

|

P5c

|

K41245

|

0.12

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

4.00~6.00

|

0.44~0.65

|

|

P9

|

S50400

|

0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.50~1.00

|

8.00~10.00

|

0.44~0.65

|

|

P11

|

K11597

|

0.05~0.15

|

0.30~0.61

|

0.025

|

0.025

|

0.50~1.00

|

1.00~1.50

|

0.44~0.65

|

|

P12

|

K11562

|

0.05~0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

0.80~1.25

|

0.44~0.65

|

|

P15

|

K11578

|

0.05~0.15

|

0.30~0.60

|

0.025

|

0.025

|

1.15~1.65

|

–

|

0.44~0.65

|

|

P21

|

K31545

|

0.05~0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

2.65~3.35

|

0.80~1.60

|

|

P22

|

K21590

|

0.05~0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

1.90~2.60

|

0.87~1.13

|

|

P91

|

K91560

|

0.08~0.12

|

0.30~0.60

|

0.02

|

0.01

|

0.20~0.50

|

8.00~9.50

|

0.85~1.05

|

|

P92

|

K92460

|

0.07~0.13

|

0.30~0.60

|

0.02

|

0.01

|

0.5

|

8.50~9.50

|

0.30~0.60

|

MECHANICAL PROPERTIES

|

A335 Low-Alloy Pipe

|

UNS Number

|

Yield Strength ksi

|

Tensile Strength ksi

|

Elongation %

|

Rockwell

|

Brinell

|

|

P1

|

K11522

|

30

|

55

|

30

|

–

|

–

|

|

P2

|

K11547

|

30

|

55

|

30

|

–

|

–

|

|

P5

|

K41545

|

40

|

70

|

30

|

–

|

207 max

|

|

P9

|

S50400

|

30

|

60

|

30

|

–

|

–

|

|

P11

|

K11597

|

30

|

60

|

20

|

–

|

–

|

|

P12

|

K11562

|

32

|

60

|

30

|

–

|

174 max

|

|

P22

|

K21590

|

30

|

60

|

30

|

–

|

–

|

|

P91

|

K91560

|

60

|

85

|

20

|

–

|

–

|

TESTING REQUIREMENTS

Transverse/longitudinal: tension and flattening, hardness, bend tests- for material that has been heat-treated in batch furnaces, these tests shall be made on the 5% of the pipes from each heat lot number. For smaller lots, one pipe at a minimum has to be tested

ASTM A335 Gr. P91 shall have a hardness of 250 HB / 265 HV (25 HRC)

Hydro testing: shall be applied to every length of pipe

The non-destructive electric test is optional

التعبئة

ربما توجد مئات الطرق المختلفة لتعبئة الأنبوب ، ومعظمها له ميزة ، ولكن هناك مبدآن حيويان لأي طريقة للعمل تمنع الصدأ وأمن النقل البحري. يمكن أن تلبي التعبئة لدينا أي احتياجات للعملاء.

أغطية بلاستيكية توصيل على جانبي نهايات الأنابيب

يجب تجنب ذلك عن طريق تركيب الصلب وتلف النقل

يجب أن تكون العلامات المجمعة موحدة ومتسقة

يجب أن تأتي نفس الحزمة (الدفعة) من الأنابيب الفولاذية من نفس الفرن.

الأنابيب الفولاذية لها نفس رقم الفرن ، نفس الدرجة الفولاذية ، نفس المواصفات.

مواصفة

astm a335 steel pipe chemical composition:

|

material

|

c

|

si

|

mn

|

p

|

s

|

mo

|

cr

|

|

|

%

|

%

|

%

|

%

|

max

|

%

|

max

|

|

a335 grade p1

|

0.10---0.20

|

0.10---0.50

|

0.30---0.80

|

0.025

|

0.025

|

0.440.65

|

|

|

a335 grade p5

|

max 0.15

|

max 0.50

|

0.30---0.60

|

0.025

|

0.025

|

0.450.65

|

4.006.00

|

|

a335 grade p11

|

0.05---0.15

|

0.5---1.0

|

0.30---0.60

|

0.025

|

0.025

|

0.450.65

|

1.001.50

|

|

a335 grade p12

|

0.05---0.15

|

max 0.50

|

0.30---0.61

|

0.025

|

0.025

|

0.450.65

|

0.801.25

|

|

a335 grade p22

|

0.05---0.15

|

max 0.50

|

0.30---0.60

|

0.025

|

0.025

|

0.871.13

|

1.902.60

|

astm a335 steel pipe mechanical properties:

|

material

|

tensile n/mm2

|

strength min n/mm2

|

yield %min

|

|

a335 grade p1

|

min380

|

205

|

30

|

|

a335 grade p5

|

min415

|

205

|

30

|

|

a335 grade p11

|

min415

|

205

|

30

|

|

a335 grade p12

|

min415

|

205

|

30

|

|

a335 grade p22

|

min415

|

205

|

30

|

stm a335 steel pipe may be either hot finished or cold drawn with the finishing heat treatment noted below.

|

astm a335 grade

|

heat treatment type

|

normalizing temperature range f [c]

|

subcritical annealing or tempering

temperature range f [c]

|

|

p5 (b,c)

|

full or isothermal anneal

|

|

|

|

|

normalize and temper

|

-

|

1250 [675]

|

|

|

subcritical anneal (p5c only)

|

-

|

1325 - 1375 [715 - 745]

|

|

p9

|

full or isothermal anneal

|

|

|

|

|

normalize and temper

|

-

|

1250 [675]

|

|

p11

|

full or isothermal anneal

|

|

|

|

|

normalize and temper

|

-

|

1200 [650]

|

|

p22

|

full or isothermal anneal

|

|

|

|

|

normalize and temper

|

-

|

1250 [675]

|

|

p91

|

normalize and temper

|

1900-1975 [1040 - 1080]

|

1350-1470 [730 - 800]

|

|

|

quench and temper

|

1900-1975 [1040 - 1080]

|

1350-1470 [730 - 800]

|

ستاندرد

CHEMICAL COMPOSITION

The types of alloy steel covered by the ASTM A335 – ASME SA335 specification are designed with a “P” prefix, from P5 to P92. Grades P11/P22 and P91/92 are typically found in power stations, whereas grade P5 and P9 are more common for application in the petrochemical industry. Grades P9 and P91 are in the list, the more expensive.

|

ASTM A335

Low-Alloy Steel

(Grades)

|

UNS

equivalent

|

C≤

|

Mn

|

P≤

|

S≤

|

Si≤

|

Cr

|

Mo

|

|

P1

|

K11522

|

0.10~0.20

|

0.30~0.80

|

0.025

|

0.025

|

0.10~0.50

|

–

|

0.44~0.65

|

|

P2

|

K11547

|

0.10~0.20

|

0.30~0.61

|

0.025

|

0.025

|

0.10~0.30

|

0.50~0.81

|

0.44~0.65

|

|

P5

|

K41545

|

0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

4.00~6.00

|

0.44~0.65

|

|

P5b

|

K51545

|

0.15

|

0.30~0.60

|

0.025

|

0.025

|

1.00~2.00

|

4.00~6.00

|

0.44~0.65

|

|

P5c

|

K41245

|

0.12

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

4.00~6.00

|

0.44~0.65

|

|

P9

|

S50400

|

0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.50~1.00

|

8.00~10.00

|

0.44~0.65

|

|

P11

|

K11597

|

0.05~0.15

|

0.30~0.61

|

0.025

|

0.025

|

0.50~1.00

|

1.00~1.50

|

0.44~0.65

|

|

P12

|

K11562

|

0.05~0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

0.80~1.25

|

0.44~0.65

|

|

P15

|

K11578

|

0.05~0.15

|

0.30~0.60

|

0.025

|

0.025

|

1.15~1.65

|

–

|

0.44~0.65

|

|

P21

|

K31545

|

0.05~0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

2.65~3.35

|

0.80~1.60

|

|

P22

|

K21590

|

0.05~0.15

|

0.30~0.60

|

0.025

|

0.025

|

0.5

|

1.90~2.60

|

0.87~1.13

|

|

P91

|

K91560

|

0.08~0.12

|

0.30~0.60

|

0.02

|

0.01

|

0.20~0.50

|

8.00~9.50

|

0.85~1.05

|

|

P92

|

K92460

|

0.07~0.13

|

0.30~0.60

|

0.02

|

0.01

|

0.5

|

8.50~9.50

|

0.30~0.60

|

MECHANICAL PROPERTIES

|

A335 Low-Alloy Pipe

|

UNS Number

|

Yield Strength ksi

|

Tensile Strength ksi

|

Elongation %

|

Rockwell

|

Brinell

|

|

P1

|

K11522

|

30

|

55

|

30

|

–

|

–

|

|

P2

|

K11547

|

30

|

55

|

30

|

–

|

–

|

|

P5

|

K41545

|

40

|

70

|

30

|

–

|

207 max

|

|

P9

|

S50400

|

30

|

60

|

30

|

–

|

–

|

|

P11

|

K11597

|

30

|

60

|

20

|

–

|

–

|

|

P12

|

K11562

|

32

|

60

|

30

|

–

|

174 max

|

|

P22

|

K21590

|

30

|

60

|

30

|

–

|

–

|

|

P91

|

K91560

|

60

|

85

|

20

|

–

|

–

|

TESTING REQUIREMENTS

Transverse/longitudinal: tension and flattening, hardness, bend tests- for material that has been heat-treated in batch furnaces, these tests shall be made on the 5% of the pipes from each heat lot number. For smaller lots, one pipe at a minimum has to be tested

ASTM A335 Gr. P91 shall have a hardness of 250 HB / 265 HV (25 HRC)

Hydro testing: shall be applied to every length of pipe

The non-destructive electric test is optional

التعبئة

ربما توجد مئات الطرق المختلفة لتعبئة الأنبوب ، ومعظمها له ميزة ، ولكن هناك مبدآن حيويان لأي طريقة للعمل تمنع الصدأ وأمن النقل البحري. يمكن أن تلبي التعبئة لدينا أي احتياجات للعملاء.

أغطية بلاستيكية توصيل على جانبي نهايات الأنابيب

يجب تجنب ذلك عن طريق تركيب الصلب وتلف النقل

يجب أن تكون العلامات المجمعة موحدة ومتسقة

يجب أن تأتي نفس الحزمة (الدفعة) من الأنابيب الفولاذية من نفس الفرن.

الأنابيب الفولاذية لها نفس رقم الفرن ، نفس الدرجة الفولاذية ، نفس المواصفات.

إذا كانت لديك أي استفسارات وأسئلة ، يرجى الاتصال بنا في أي وقت. شكرا مقدما. مرحبًا!

English

English Español

Español Français

Français بالعربية

بالعربية