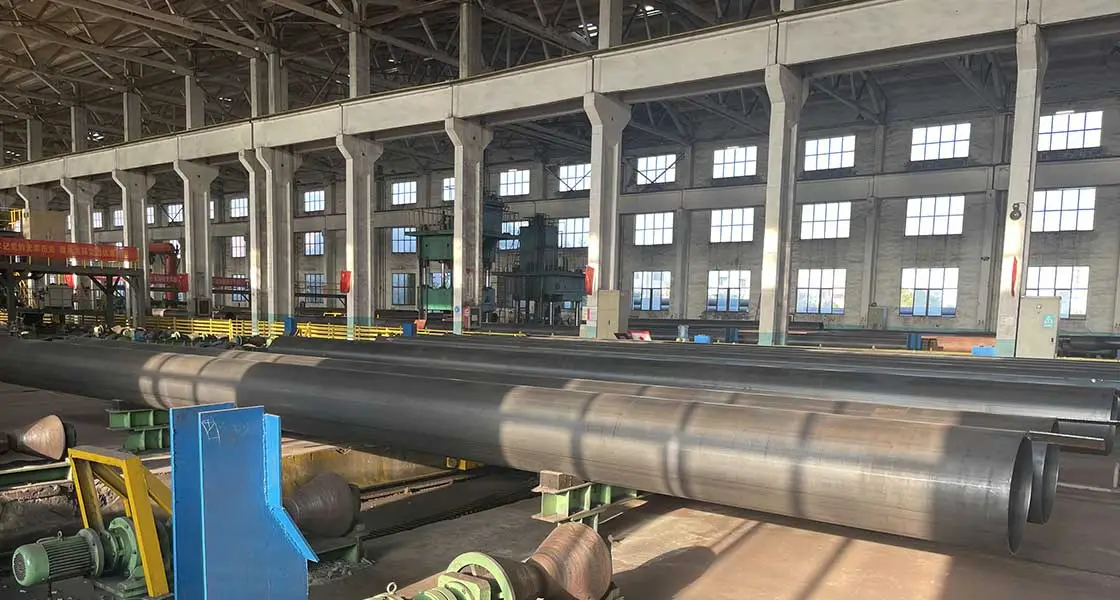

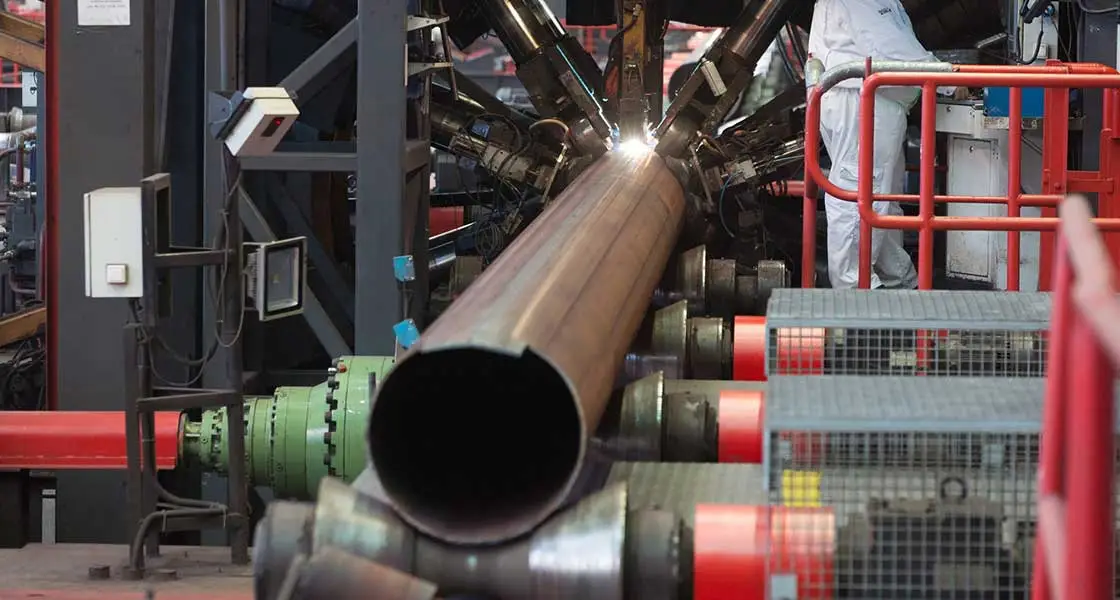

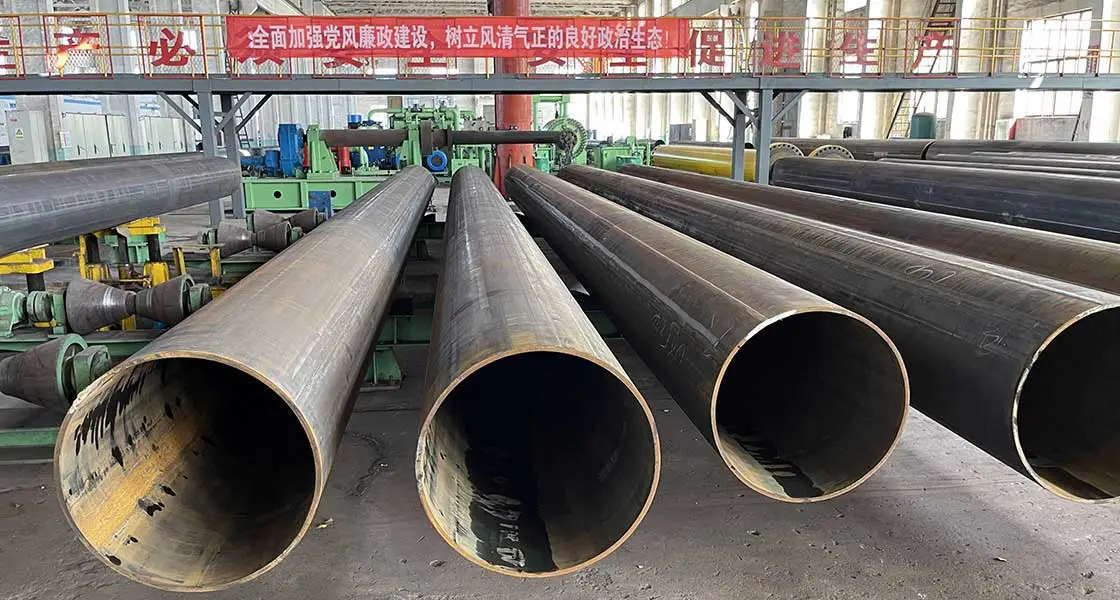

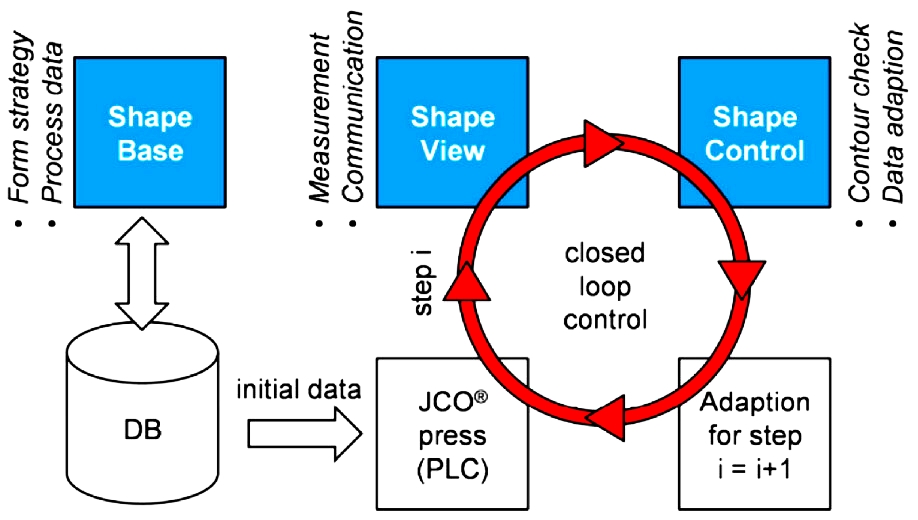

LASW Workshop introduces international JCOE production technology, specializing in the production of large-diameter straight seam double-sided submerged arc welded steel pipes. The production line adopts the full-line PID automatic control continuous J-C-O forming process, which is fast, high-quality, uniform forming stress distribution, and regular pipe shape. The production equipment is quick and simple to change, and the product specification range is large. It can produce straight seam double-sided submerged arc welded steel pipes with a diameter of 406.4mm-1422.4mm, a wall thickness of 6mm-50mm, and a length of 3m-12.5m. The material is ordinary carbon, special steel, alloy steel, and the steel grade is up to X80. The annual output reaches 150,000 tons. This product is suitable for various types of oil and gas pipelines and building steel structures. Including oil pipelines, natural gas, urban pipelines, mine water-coal slurry pipelines, high-voltage transmission lines, wind power, bridges, high-speed railway steel structure buildings, etc.

English

English Español

Español Français

Français بالعربية

بالعربية