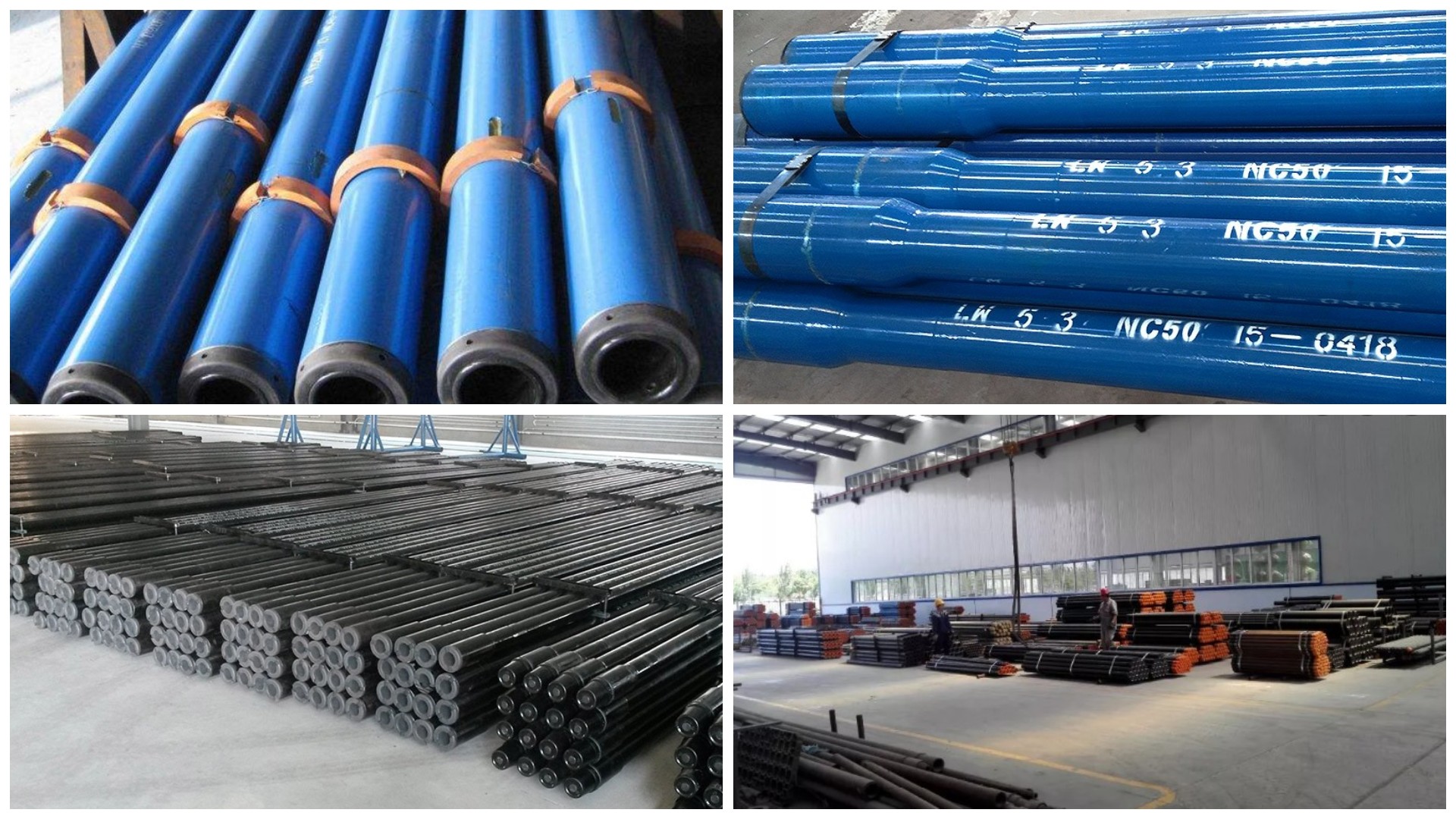

Drill Pipe Size:

OD: 60.32mm-168.28mm

WT: 6.45-12.7mm

LENGTH: R1, R2, R3

Heavy Weigh Drill Pipe

OD: 2-3/8" to 6-5/8"

LENGTH:,Range 2 and 3

Grades: E75, X95, G105, S135

Connection threads:NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH.

Pipe Standard:API 5DP E75, X95, G105, S135

Upset Style:IU, EU, IEU

Connection:NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH.

Application: Drill pipe is for exploration and development of oil and gas wells.

Drill Collars

- OD: 3 1/8"-11"

- Length: 30Ft / 31Ft / 43Ft / R1~R3

- Standard: API 5DP/API Spec 7-1 E75,X95,G105,S135

- Connection Type: NC, REG, FH, IF

- Thread: NC26, NC31, NC38, NC40, NC46, NC50,5.1 / 2FH

- Material: Stainless Steel / Alloy Steel /Carbon Steel / 4145H

- Classification: Non Magnetic Drill Collar, Slick Drill Collar, Spiral Drill Collar,Square Drill Collars, Monel Drill Collar, Pony Drill Collar, Spesifikasi Drill Collar

Application

- Oil And Gas Well Drilling

- Oilfield Drilling

- Mine Blasting

- Water Well Drilling

- Geothermal Wells Drilling

- Fore Poling

- Coal And Nonferrous Metal Mining Projects

If you have any Inquiry, please don't hesitate to contact us immediately,Email:sales@super-steels.com

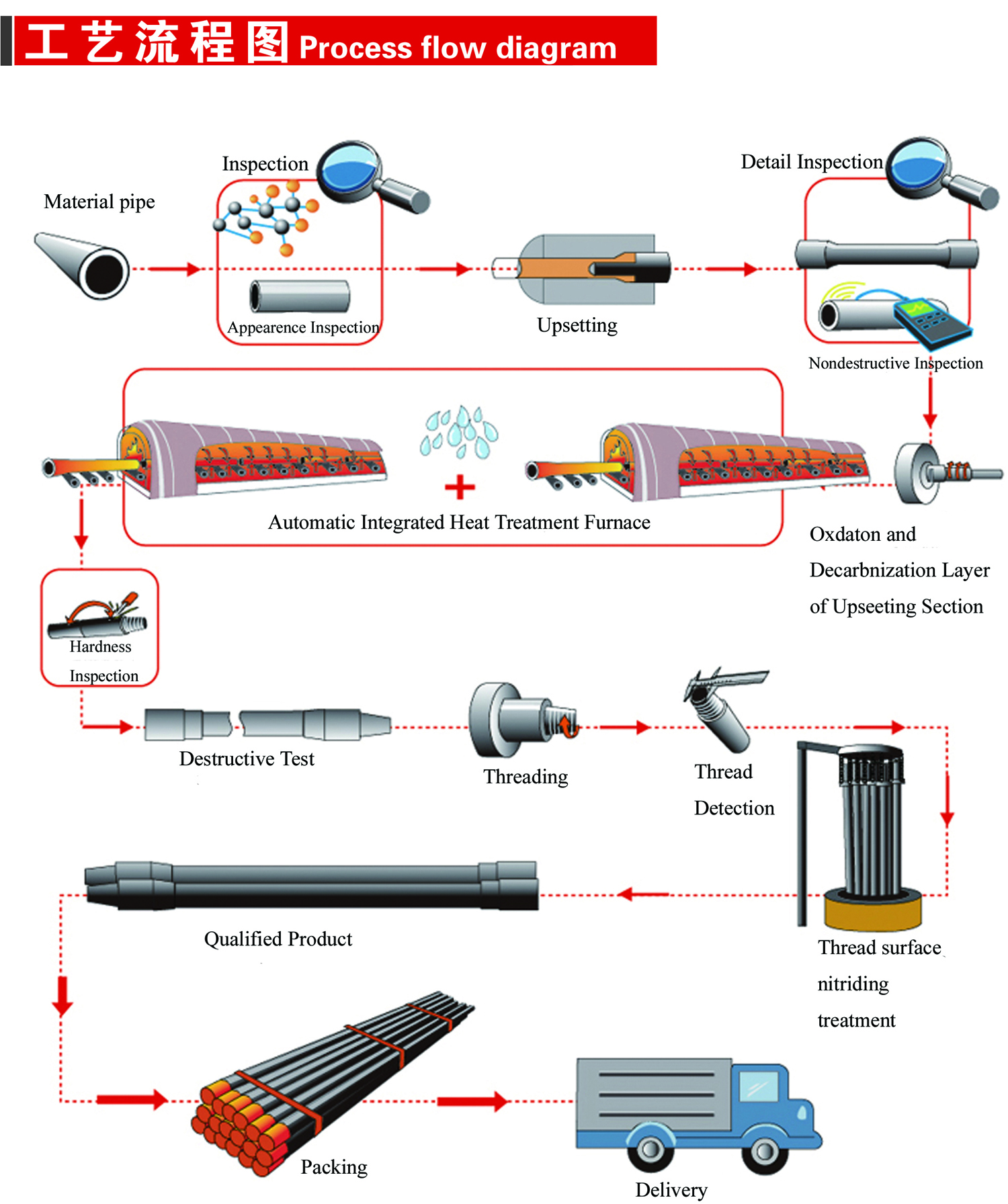

Drill pipe is a steel pipe with thread at the end, which is used to connect the surface equipment of the drilling rig to the drilling and grinding equipment or the bottom hole equipment at the bottom of the drilling. Drill pipe can be divided into three categories: kelly, drill pipe and heavy drill pipe.

Drill collar is located at the bottom of the drill string and is the main component of the lower drill tool assembly. Its main feature is that the wall thickness is larger, and it has greater gravity and rigidity. In order to facilitate tripping work, elevator grooves and slip grooves can be processed on the outer surface of the inner thread of the drill collar. Drill collars are generally divided into three types: spiral drill collars, non-magnetic drill collars, and integral drill collars.

English

English Español

Español Français

Français بالعربية

بالعربية