qualified standard

gb/t3091 welded steel pipe for low pressure liquid delivery

gb/t9711 petroleum and natural gas industries--steel pipe for pipelines

is: 3589 steel tubes for water and sewage

is : 1978-1982:steel tubes for use in transportation of oil; gas & petroleum products

astm a53 standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded and seamless

din 2458 welded steel pipes and tubes

en10217 welded steel tubes for pressure purposes. technical delivery conditions.

non-alloy steel tubes with specified room temperature properties

api 5l line pipe

sy/t5037 spiral submerged arc-welded steel pipe for pipelines for low pressure field fluid service

sy/t 5040 spiral submerged arc-welded steel pipe piles

cj/t 3022 spiral submerged-arc welded steel pipe for municipal heat supply

is : 1978 steel tubes for use in transportation of oil; gas & petroleum products

astm a252 welded and seamless steel pipe piles

coating standard

ansi/awwa c104/a21.4 american national standard for cement-mortar lining for ductile-iron pipe and fittings for water

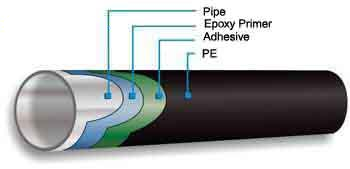

iso 21809 petroleum and natural gas industries -- external coatings for buried or submerged pipelines used in pipeline transportation systems

din 30670 polyethylen coatings of steel pipes and fittings

English

English Español

Español Français

Français بالعربية

بالعربية