Structural box beams are beams with a hollow rectangular or square cross-section, giving them a unique box-like shape. This design allows them to handle significant weight while remaining lightweight. They are often used for long-span applications, where strong and durable beams are needed without additional weight or bulk.

The hollow nature of box beams helps distribute stress evenly, making them highly efficient in terms of both material use and performance. These beams are commonly fabricated from materials like steel, aluminum, or concrete, depending on the needs of the specific project.

Material: Q235B, Q355B,A36,S275

Standard: GB,EN1900,AISC,JIS,CWB

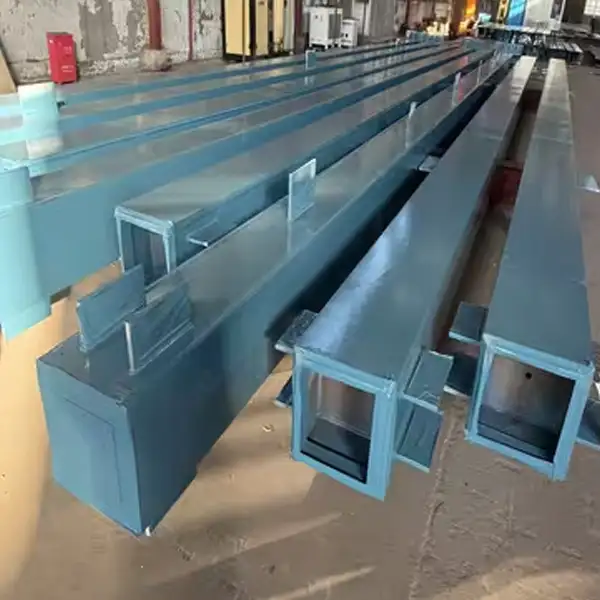

Surface Treatment: 1.Painting 2.Galvanized

Application: Steel Structure Fabrication, Prefabricated Building

Processing Service: Bending, Welding, Decoiling, Cutting, Punching

Package: GP Containers (40 Feet),Break Bulk

Highlight: Prefabricated Steel Structure Fabrication, Building Steel Structure Fabrication, Box Steel Components

Applications of Box Beams

Bridge Construction

One of the most common applications of structural box beams is in bridge construction. Due to their high load-bearing capacity and ability to span long distances with fewer supports, box beams are used to support bridge decks, ensuring stability while minimizing the number of support columns. Their lightweight design allows for easier transportation and placement, reducing the time and costs associated with building bridges.

High-Rise Buildings

In skyscrapers and multi-story buildings, box beams are often integrated into the overall structural design. These beams can support both vertical and horizontal loads, which reduces the need for numerous columns and increases the usable floor area. Their ability to support high loads without increasing the weight of the structure makes them ideal for tall buildings.

Commercial and Industrial Buildings

Structural box beams are widely used in large commercial and industrial buildings, such as warehouses and factories, where open floor space is required. They are often used to support large roofs, offering significant strength and flexibility without the need for multiple support columns in the building’s interior.

English

English Español

Español Français

Français بالعربية

بالعربية