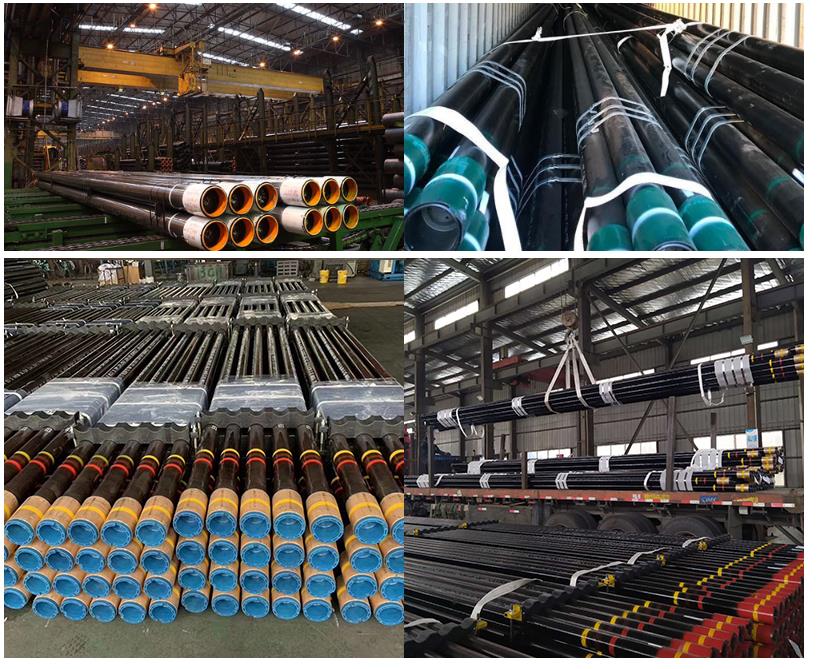

pipe type: oil casing, api 5ct casing,api spec 5ct j55 k55 n80 l80 casing pipe;seamless steel oil well casing pipe

outer diamater(od):114.30mm-508mm

wall thickness(wt): 5.21mm-16.13mm

length: r1; r2; r3

gread:j55;k55;n80-q;l80-1;l80-9cr;l80-13cr,c95,p10

standard: api 5ct psl1/psl2 j55,k55,n80-1,n80-q, api 5ct psl1/psl2 l80-1, l80-9cr,l80-13cr,c90, c95, p110, q125

thread types: stc;ltc;btc;vam top equivalent;new vam equivalent;cs equivalent;hsc equivalent;nue;eue;ltc;xc

thread: nue, eue, vam, stc, ltc, btc, xc, vam top, new vam,hydrill cs

application: casing pipe is widely used for fastening oil and gas well wall or borehold, with bigger diameter than tubing, including surface casings, technical casings and oil layer casings.

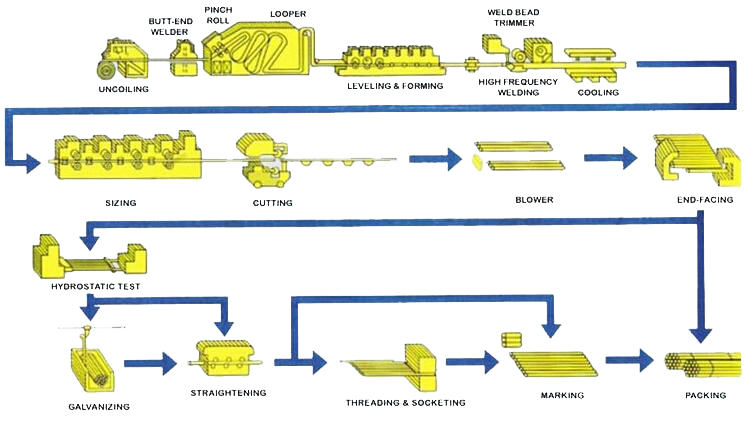

production technology: plain pipe-end upsetting- austenite treatment-quenching-tempering-straightening-(non-destructive testing)- threading-thread inspection-coupling mpi-phosphating-coupling make up-drifting-hydrostatic testing-measuring&weight-marking&stenciling-coating-packing casing and tubing-transportation

vailable sizes

category: erw, hfw or smls

standards:h-40, j-55, k-55, c-75, l-80, n-80, c-95, as-95, p-110, l80-13cr

steel grade: h40, j55, k55, n80

connections

api 5ct is applicable to following connections which complied with api spec 5b:

• sc: short round thread casing

• lc: long ound thread casing

• bc: buttress thread casing

• nu: non-upset tubing

• eu: external upset tubing

English

English Español

Español Français

Français بالعربية

بالعربية