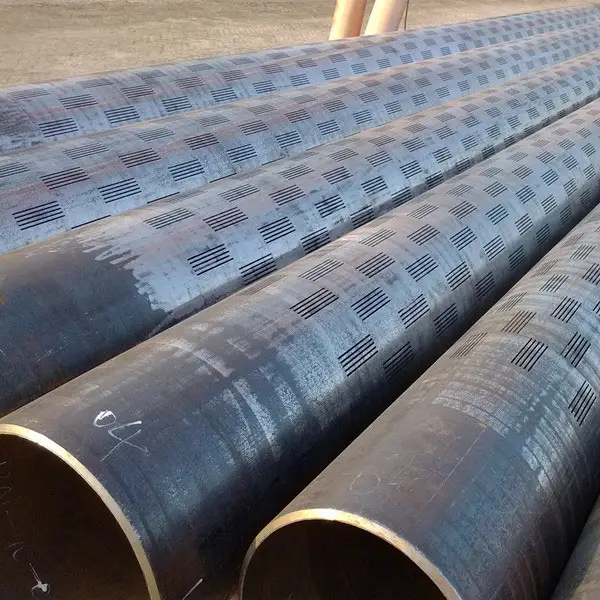

Product Name: Slotted Pipe, Slotted Casing, Slotted Steel Pipe

Application: Used As Walls Structural Retainers And Screen Pipes For Oil, Gas And Water Wells

Od: 50mm - 500mm

Wt: Less Than20mm

Length: Less Than 15m

Slot&Holes Specification: As Customer Require

Standard & Grade: Api 5ct J55/K55/N80/C75/L80/C90/T95/Q125

Process Type: Seamless (Smls), Electric Resistance Welded(Erw)

End: Plain, Beveled, Square Cut, With Ltcistc/Btc Connection

Surface: Anti-Corrosion&Water Painting

Packing: Protection Caps In Both Ends, Waterproof Paper Wrapped

Slot And Perforate On The Pipe Body To Be Slotted Pipes. The Types Of Slot Are Perforated,Rectangular Slotted, Trapezoid Slotted, Bridge Slotted, Wire Wrapped Screen, Mechanical Cutting, Compound Slotted Pipe. The Slotted Pipe Is Using In Oil Exploration To Prevent Sand, Decrease Oil Well Repaired, Increase Oil Wells Strength,Integrality And Stability Of Keeping Off Sand.

Slotted Casing Pipe Specification

O.D.: Casing: 4 1/2"-20"(114.3mm-508mm); Tubing:1.05"-41/2"(26.7mm-114.3m)

Length: R1:4.88-7.62m,R2:7.621-10.36m,R3:10.36-14.63m

W.T.: 0.205”"-0.875” (5.21mm- 22.22mm)

Product Standards: Api 5ct, Bs En Iso11960,Nfm87-207,Jis G3439,Iso 4270,Gost632-80

Material: H40,J55,K55,N80-1,N80q, R95,L80-1,L80-9cr,L80-13cr, C90,T95,C110,P110,Q1252.

Casing: Stc,Ltc,Btc Etc.

Tubing: Nu, Eu,Xl,Ph-4,Ph-6,Ltc,Stc,Btc Etc.

Advantages Of Union Steel Slotted Pipe

1. Our Perforated Pipe Use J55/K55/N80 Casing And Tubings Of Api Standard, With High Overall Strength, Not So Easy To Deformation.

2. The Edge Of The Slot Is Vertical, Smooth, Without Burrs, And The Slot Is Uniformity.

3. The Perforated Pipe Is Suitable For Sandy Well, Which The Diameter Of The Sand Greater Than 0.3mm.

4. The Slot Can Be Longitudinal And Transverse, The Section Of The Slot Can Be Parallel And Trapezoidal Types, With A Wide Open Area.

5. Slotted Screen Pipe Has A Big Inner Diameter.

English

English Español

Español Français

Français بالعربية

بالعربية