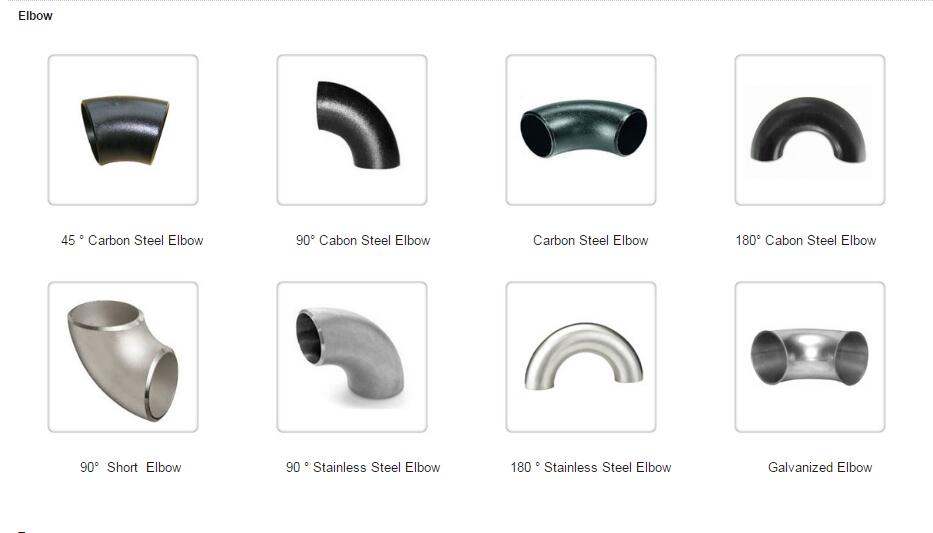

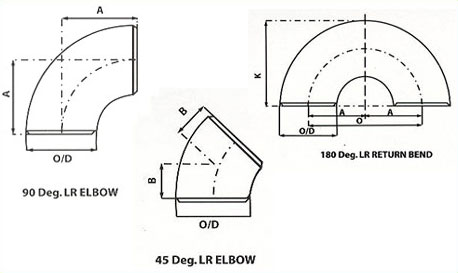

Pipe Type: 45 Degree,90 Degree,180 Degree Elbow,Long Radius,Short Radius Elbow

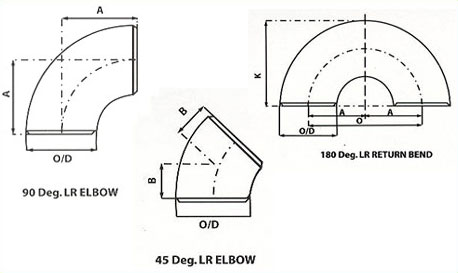

Size: Nps: 1/2''~24''(Seamless), 24''~72''(Welded);Dn: 15~1200,

Wt: 2~80mm, Sch 5~Xxs

Bending Radius: R=1d~10d, R=15d, R=20d

Material & Standard:

Carbon Steel --- Asme B16.9, Astm A234 Wpb

Stainless Steel --- Astm A403 304/304l/310/310s/316/316l/317l/321 ;

Alloy Steel --- Astm A234 Wp1/5/9/11/12/22/91

Ends: Square Ends/Plain Ends (Straight Cut, Saw Cut, Torch Cut), Beveled/Threaded Ends

Packing: Packed In Wood Cabins/Wood Tray

Usage: For Conveying Gas, Water And Oil Either In The Oil Or Natural Gas Industries

elbow is a pipe fitting which is used as a connection point between two lengths of pipes to produce a change in the direction of flow in the pipe, usually at an angle of 90°, 45° or 180°. elbows are also commonly referred as bends, and are available in a range of materials such as stainless steel, carbon steel, alloy steel, nickel alloys, duplex, and cupro nickel.

also known as 90° bends, 90° elbows are manufactured as sr (short radius) elbows and lr (long radius) elbows. 45° elbows are typically made as lr (long radius) elbows.

the long radius elbows have a center to end distance that is 1.5 times the nps in inches (r=1.5d), while the short radius is equal to the nps in inches (r=1.0d).=short radius elbows are generally used in tight areas, and long radius elbows are used when space is available and flow is more critical. we can also manufacture and supply carbon steel elbows and stainless steel elbows in non-standard size angles such as 60°, 100°, 120° or 150°.

the ends may be machined for butt welding, threaded (usually female), or socketed, etc. when the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

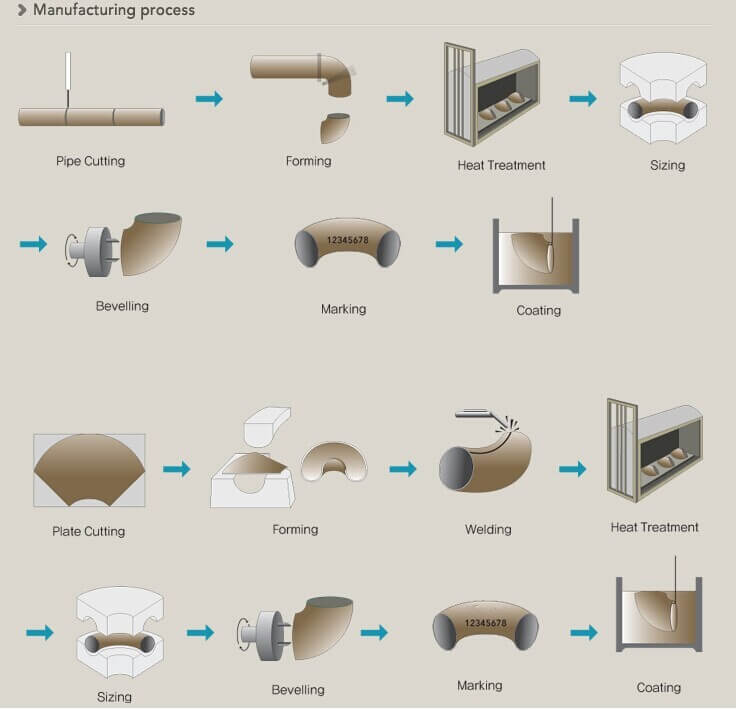

Seamless Elbow Manufacturing Process (Heat Bending & Cold Bending)

One of the most common methods for manufacturing elbows is using hot mandrel bending from straight steel pipes. After heating the steel pipe at a elevated temperature, the pipe is pushed, expanded, bend by the inner tools of mandrel step by step. Applying hot mandrel bending can manufacture a wide size range seamless elbow. The characteristics of mandrel bending are strongly depend on the integral shape and dimensions of the mandrel. The using advantages of hot bending elbows include smaller thickness deviation and stronger bending radius than other bending method type. Meanwhile, using bending instead of prefabricated bends substantially reduces the number of welds needed. This reduces the amount of work required and increases the quality and usability of pipes. However, cold bending is the process to bent the straight steel pipe at normal temperatures in a bending machine. Cold bending is suitable for pipes with an outer diameter of 17.0 to 219.1 mm, and wall thickness 2.0 to 28.0 mm. The recommended bending radius is 2.5 x Do. Normally at a bending radius of 40D. By using cold bending, we can get small radius elbows, but we need to pack the internals with sand to prevent wrinkling. Cold bending is a quick and inexpensive bending method. It is a competitive option for making pipelines and machine parts.

Welded Elbow Manufacturing Process (Small & Large)

Welded elbows are made from the steel plates, so it is not seamless steel elbows. Use a mould and press the steel plate to the shape of the elbow, then weld the seam to be a finish steel elbow. It is the old production method of the elbows. Recent years the small sizes elbows are almost manufactured from the steel pipes now. For the big size elbows, for example, it is very difficult to produce elbows over 36'' OD from the steel pipes . So it is commonly made from the steel plates, pressing the plate to the shape of half elbow, and welding the two halves together. Since the elbows are welded in its body , the inspection of the welding joint is necessary . Commonly we use the X-Ray inspection as the NDT.

English

English Español

Español Français

Français بالعربية

بالعربية