|

Out Diameter

|

13.7mm-914mm

|

|

Wall Thickness

|

2mm-120mm

|

|

Length

|

2m-12m

|

|

Producing Standard

|

American Asme B36.10m, Astm Api 5l, Api 5ct

Japanese Jis, German Din, Chinese Gb, Bs Standard

|

|

Steel Grade

|

ASTM A53, A106, A210, A252, A178, A333, A335, SAE1018, SAE1020, SAE1045 ETC;

API 5L PSL1: A, B, X42, X46, X52, X56, X60, X65, X70

API 5L PSL2: B, X42, X46, X52, X56, X60, X65, X70, X80JIS SS400, STPG42, G3454, G3456 ETC;

DIN ST35, ST35.8, ST37, ST42, ST45, ST52, DIN1626, DIN17175 ETC;

GB 10#, 20#, 45#, Q235, Q345, Q195, 16MN, 27SIMN, 20CR, 40CR, 12CRMO, 15CRMO, 30CRMO, 35CRMO, 42CRMO ETC;

|

|

Special Specifications

|

Available According To Customer's Requirements And Quantity.

|

|

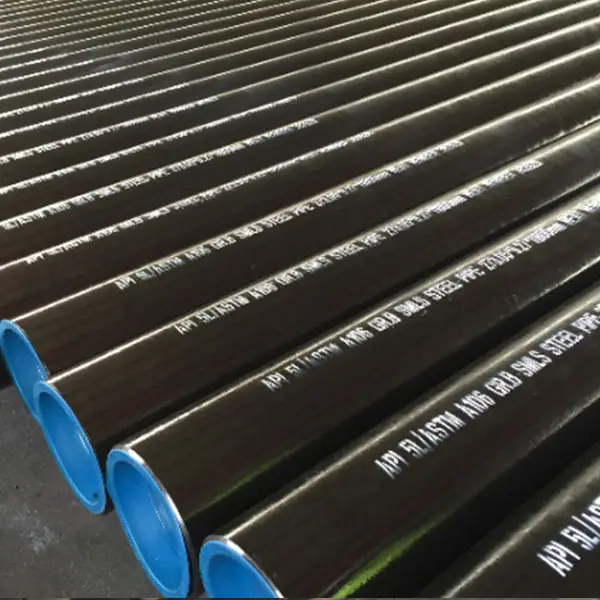

End Shape

|

Beveled End, Plain End, Varnished, Or Adding Plastic Caps To Protect The Two Ends As Per Customer's Requirements

|

|

Surface Treatment

|

Painted, Oiled, Galvanized, Phosphate Etc

|

|

Usage

|

1.Widely Used In The Mechanical Treatment Field, Petrochemical Industry, Transport And Construction Field

2.Ordinary Structural Purposes And Mechanic Structural Purposes, For Example In Construction Field, Fulcrum Bearing Etc;

3.The Transportation Of Fluids In The Projects And Big Equipments, For Example Transport Of Water, Oil, Gas Etc

4.Can Be Used In Low And Medium Pressure Boiler For The Transportation Of Fluids, For Example Steam Tube, Big Smoke Tube, Small Smoke Tube, Generating Tube Etc

|

astm a106 is a specification for seamless carbon steel pipe for high-temperature service. it has a maximum carbon content of 0.30% and a maximum manganese content of 1.20%, making it a low-carbon steel with good strength and toughness. this material is suitable for use in high-temperature and high-pressure applications, such as power generation, chemical processing, and petroleum refining. additionally, it has excellent corrosion resistance and can be used in outdoor environments without requiring additional protection.

the normal use cases for astm a106 include transportation of fluids and gases, as well as structural applications in the construction industry. it is also commonly used in the manufacturing of boilers, heat exchangers, and pressure vessels. its strength, toughness, and corrosion resistance make it a popular choice for a wide range of applications that require durability and reliability in high-temperature environments.

English

English Español

Español Français

Français بالعربية

بالعربية