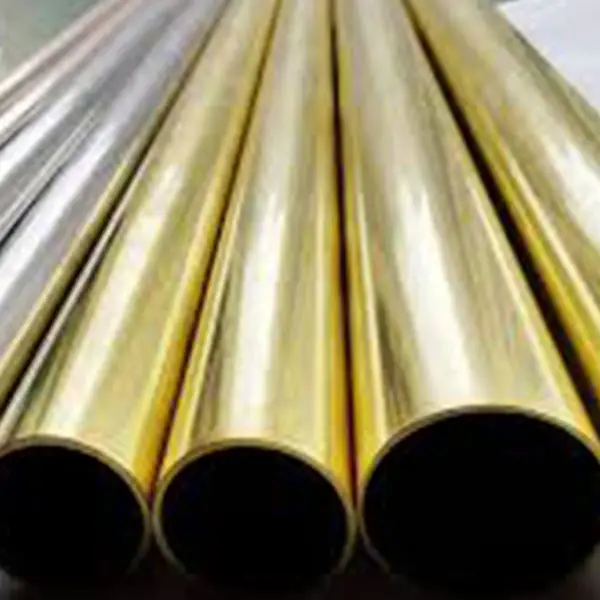

Aluminium Brass Pipe

Aluminum Brass Tube

Aluminum Brass Tube is a copper zinc alloy containing aluminum and small amount of arseric which is added as an inhibitor against dezincification. Inhibited Aluminum Brass resists the action of high velocity salt and brackish water and is commonly used for condenser tube.

The outstanding characteristic of Aluminum Brass is th high resistance to impringement attack.

Aluminum Brass tubes are highly accepted and one of the extensively used material for various industrial applications.

Product Range

-

Outside diameter : 5.0 mm(min) ~ 65 mm(max)

-

Wall thickness : 0.5mm(Min.)

-

Length : 27,000mm(Max.)Single Random, Double Random & Cut Length

-

Product capacity per month : 500 M.T.

-

U-bend tube (smallest bending radius ≥ 2 x tube O.D.)

-

Form:Round, Square, Rectangular, Hydraulic Etc

-

Type:Seamless / Heat Exchangers / Condenser Tubes

-

Aluminium Brass Tubes:ASTM B 111 C 68700,ASME SB 111,C 68700

,BS 2871 PART 3 CZ – 110,EN 12451 CuZN20 AL2As,NFA 51 102,CuZn22 Al2,JIS H – 3300 C 6870

Application :

Steam Ejector, Intor and After Condensers, Grand steam condensers, Feed Water Evaporators for Petrochemical, Ship-building, Power plants and Desalination plants etc.

English

English Español

Español Français

Français بالعربية

بالعربية