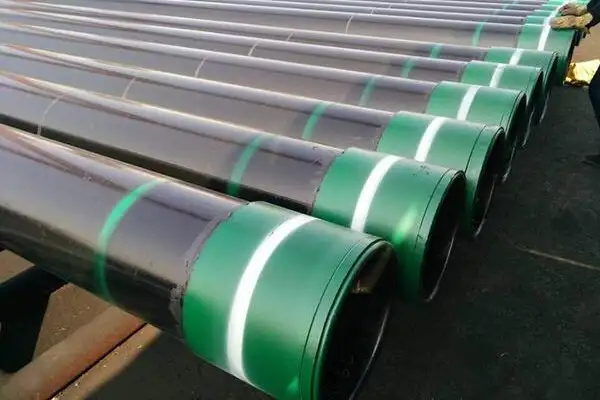

Non-standard seamless steel pipes (non-standard smls pipes) refer to pipes whose dimensions, materials, or performance characteristics do not fully comply with existing public standards such as GB/T 8162 "Seamless Steel Pipes for Structures" or GB/T 8163 "Seamless Steel Pipes for Transporting Fluids". These pipes are primarily designed to fill the gaps where standard specifications fall short in real-world applications. In practice, non-standard smls pipes are essential in scenarios where national standard products cannot meet specific requirements — such as special engineering projects, equipment repairs, customized products in small batches, or material and process testing. For example, in the manufacture of large, specialized equipment, pipes with unique dimensions or materials may be required. Non-standard pipes can effectively fulfill these special needs.

English

English Español

Español Français

Français بالعربية

بالعربية