Steel sheet piles are sections of sheet materials with interlocking edges that are driven into the ground to provide earth retention and excavation support. Sheet piles are commonly used for retaining walls, land reclamation, underground structures such as car parks and basements, in marine locations for riverbank protection, seawalls, cofferdams, and so on.

For most engineering projects, installing sheet piles is typically used for scaffolding or temporary excavation protection applications. These include basement and tunnel construction.

Product Name: Steel Sheet Pile,Interlocking Sheet Pile

Type: Z Type, U Type, Cold Formed, Hot Rolled

Standard: JIS A 5523 : 2012,JIS A 5528 : 2012,BS EN 10248-1 : 1996,BS EN 10248-2 : 1996,ASTM A572M/A572-12,ASTM A6/A6M-12

Applications: Levee Strengthening, Retaining Walls, Breakwaters, Bulkheads, Environmental Barrier Walls, Bridge Abutments, Underground Parking Garages

Features of Steel Sheet Pile

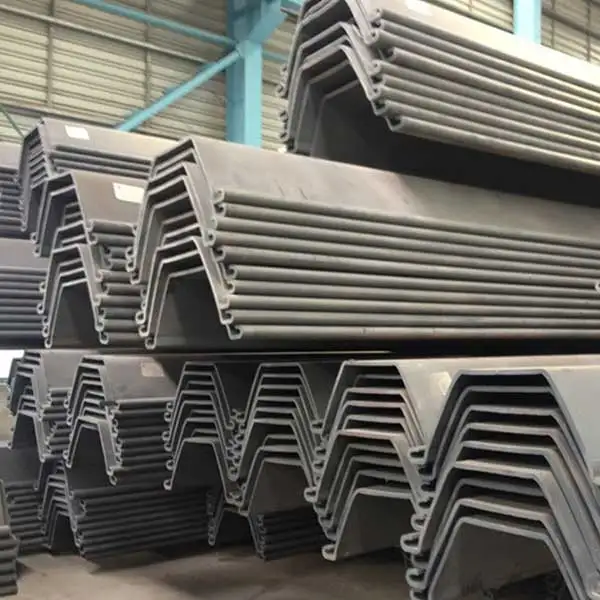

Wide Selection of Shapes and Types

Sheet pile is available in a wide range of section modulus per meter of pile wall, ranging from 874 to 21,846 cm³/m. This allows selection of the most economical type of sheet pile to meet the design requirements and the intended construction method.

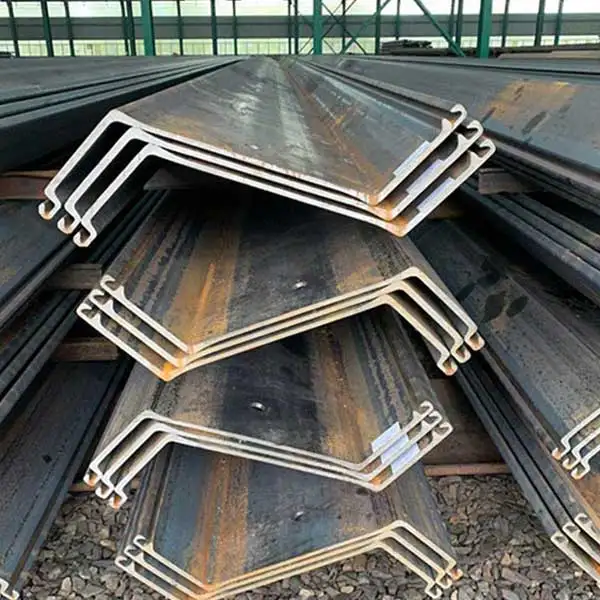

Superb Drivability and Watertightness

The clearance between the two threaded interlocks is moderate enough to ensure both excellent drivability and reliable watertightness.

Types of Steel Sheet Piles

Z Type Sheet Piles

U Type Sheet Piles

Cold Formed Sheet Piles

Hot Rolled Sheet Piles

Advantages of Steel Pile Sheets

- A sustainable option as made of recycled steel and the piles can often be reused

- Available in numerous combinations of size and weight

- Immediate barrier to prevent soil loss and sloughing during excavation

- Permanent sheet piles are designed to provide long service life

Applications of Sheet Pile Sections

- Levee Strengthening

- Retaining Walls

- Breakwaters

- Bulkheads

- Environmental Barrier Walls

- Bridge Abutments

- Underground Parking Garages

English

English Español

Español Français

Français بالعربية

بالعربية