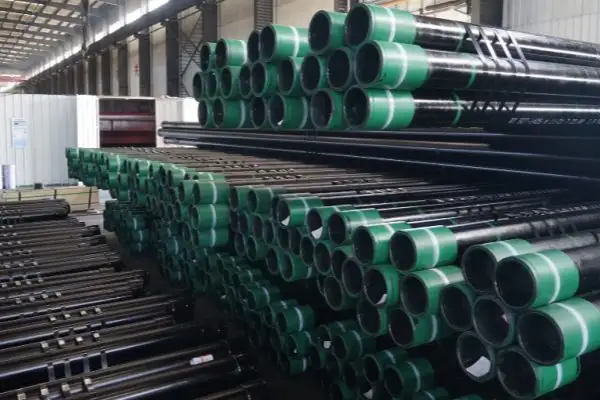

ASTM A335 Grade P22 alloy steel seamless pipes are carbon steel pipes that include chromium, molybdenum, and sometimes vanadium as alloying elements. Chromium enhances high-temperature strength, improves oxidation resistance, and increases the tensile, yield, and hardness properties at room temperature. Molybdenum, on the other hand, contributes to greater strength, elastic limit, wear resistance, impact toughness, and hardenability. It also improves the steel's resistance to softening, prevents grain growth, and reduces the susceptibility of chromium steel to embrittlement. Molybdenum is particularly effective in increasing high-temperature creep resistance, while also enhancing corrosion resistance and inhibiting pitting. Grade P22 is specifically designed for high-temperature service applications and is tolerant to variations in its microstructure.

English

English Español

Español Français

Français بالعربية

بالعربية