API 5L pipes are carbon steel seamless or welded line pipes specified by the American Petroleum Institute for transporting oil, gas, water, and fluids in pipeline systems under high pressure and harsh environments.

Key Industries Using API 5L Pipes

Oil & Gas Pipelines (onshore & offshore)

Construction & Infrastructure

Manufacturing & Industrial Systems

Power Generation Facilities

API 5L pipes are selected primarily for pressure resistance, mechanical strength, corrosion tolerance, and long-term reliability, making them essential in critical pipeline systems worldwide.

Why API 5L Pipes Matter in Oil & Gas

API 5L pipes are engineered for long-distance transportation of crude oil, natural gas, and refined products.

They are designed to withstand:

High internal pressure

Extreme temperature variations

Corrosive media and sour service environments

Compliance with API 5L minimizes pipeline failure risks, environmental hazards, and unplanned shutdowns.

API 5L Specification Overview

What Is API 5L?

API 5L is an American Petroleum Institute specification covering seamless and welded steel line pipes used in petroleum and natural gas pipeline transportation systems.

Covered grades include:

B, X42, X52, X60, X65, X70

Each grade defines:

Chemical composition limits

Mechanical performance thresholds

Mandatory testing requirements

API 5L Product Specification Levels

API 5L PSL1 vs PSL2 (Quick Comparison)

|

Item

|

PSL1

|

PSL2

|

|

Quality Level

|

Standard

|

Enhanced

|

|

Chemical Control

|

Basic

|

Strict

|

|

Mechanical Properties

|

Standard

|

Higher

|

|

CVN Impact Test

|

Not required

|

Required

|

|

Application

|

Normal service

|

High-risk / critical pipelines

|

Manufacturing Processes of API 5L Pipes

- API 5L Seamless (SMLS) Pipes

No welded seam

High pressure resistance

Limited diameter range

Higher cost

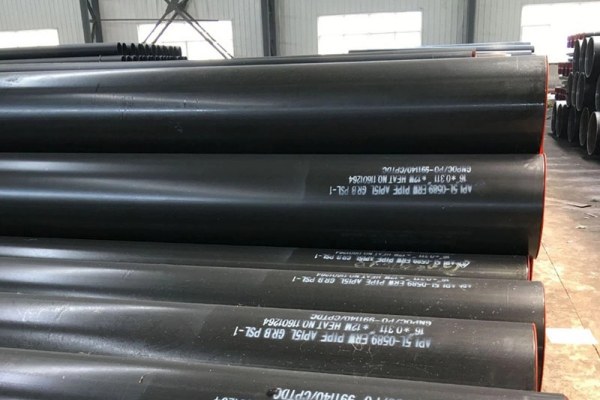

- API 5L ERW Pipes

Electric resistance welded

Cost-effective

Medium pressure applications

Weld seam inspection required

- API 5L DSAW Pipes (LSAW / SSAW)

Double submerged arc welding

Large diameter & thick wall

Oil & gas trunk pipelines

Higher manufacturing complexity

Sizes & Dimensions of API 5L Pipes

Seamless pipes: 2″ NPS – 36″ OD

ERW pipes: 2″ NPS – 24″ OD

DSAW pipes: 20″ – 48″ OD

Size selection depends on pressure rating, flow capacity, and installation conditions.

Testing & Quality Control of API 5L Pipes

API 5L pipes undergo mandatory testing, including:

Hydrostatic pressure testing

Ultrasonic testing (UT)

Radiographic testing (RT)

Charpy V-Notch impact testing (PSL2)

These tests ensure structural integrity and operational safety.

API 5L Grades Explained

API 5L grades indicate minimum yield strength:

X42 → 42,000 psi

X52 → 52,000 psi

X60 / X65 / X70 → High-pressure pipelines

Higher grades allow thinner walls at the same pressure rating, reducing total pipeline weight.

Coating & Lining of API 5L Pipes

Common protective systems:

3LPE / 3LPP

Fusion Bonded Epoxy (FBE)

Internal epoxy lining

Coatings extend service life and improve flow efficiency.

Global Standards & Equivalents of API 5L Pipes

API 5L is internationally recognized and technically aligned with:

ISO 3183

Selected ASTM pipeline standards

This ensures global project compatibility.

FAQ

FAQ 1: What are API 5L pipes used for?

API 5L pipes are used for transporting oil, gas, water, and fluids in pipeline systems across oil & gas, construction, power, and industrial sectors.

FAQ 2: What is the difference between API 5L PSL1 and PSL2?

PSL2 pipes have stricter chemical limits, higher mechanical requirements, and mandatory impact testing, making them suitable for critical pipelines.

FAQ 3: Are API 5L pipes seamless or welded?

API 5L pipes include seamless (SMLS), ERW, and DSAW (LSAW/SSAW) types, depending on size, pressure, and application.

FAQ 4: What are common API 5L grades?

Common grades include B, X42, X52, X60, X65, and X70, classified by minimum yield strength.

FAQ 5: Is API 5L equivalent to ISO 3183?

Yes. API 5L and ISO 3183 are technically equivalent pipeline standards used globally.

API 5L pipes provide standardized, high-strength pipeline solutions for oil, gas, and industrial fluid transportation. Their defined grades, testing requirements, and global acceptance make them a preferred choice for critical pipeline projects worldwide.

English

English Español

Español Français

Français بالعربية

بالعربية