ASME SA213, ASTM A213 / A 213M T11, T12, T22, T2, T5, T5b, T5c, T9, T91 is the standard applicable to seamless alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

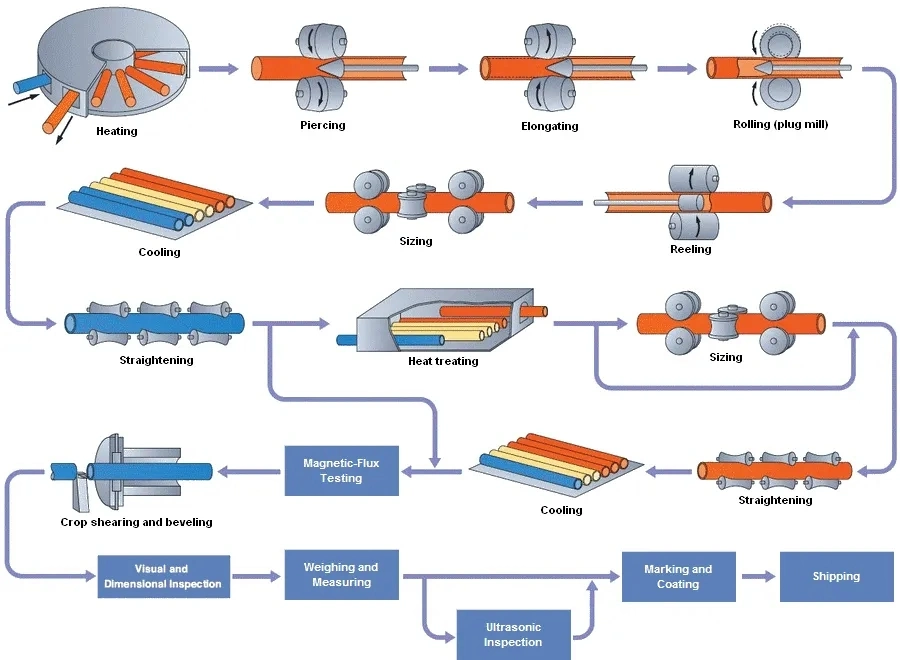

ASME SA213 /SA213M tubes shall be made by the seamless process and shall be either hot-finished or cold finished as specified.

ASME SA213 /SA213M covers several grades of minimum- wall-thickness, seamless, alloy-steel, boiler and superheater tubes.

ASME SA213 /SA213M tubing sizes and thicknesses usually furnished to this specification are 1⁄8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order, average wall thickness. Tubing having other diameters may be furnished, provided such tubes comply with all other requirements of this specification.

Standard: ASME SA213 /SA213M

Description Name: ASME SA213 / ASTM A213 T11 Seamless tubes, ASTM A213 / ASME SA213 T12 Seamless tubes, ASTM A213 / ASME SA213 T22, Seamless alloy tubes, ASTM A213 T11 Superheater tubes, ASTM A213 T12 Superheater tubes, ASTM A213 T22 Superheater tubes, ASTM A213 T11 boiler tubes, ASTM A213 T22 boiler tubes, ASTM A213 T12 boiler tubes, Seamless superheater tubes, Boiler tubes.

|

Carbon

|

Chromiun

|

Low Temperature

|

Stainless Steel

|

Duplex

|

Copper& Bronze

|

Titanium

|

Ni-Alloy

|

|

SA178-A

|

SA213-T1

|

SA333-Gr.1

|

SA213

|

TP316L

|

A789-S31803

|

SB111-C70600

|

SB338-GR.1

|

SB163

|

NO2200

|

|

SA178-C

|

SA213-T11

|

SA333-Gr.3

|

SA249

|

TP316H

|

A789-S32205

|

SB111-C71500

|

SB338-GR.2

|

SB167

|

NO2201

|

|

SA179

|

SA213-T12

|

SA333-Gr.6

|

SA268

|

TP316Ti

|

A789-S32750

|

SB111-C71640

|

SB338-GR.5

|

SB444

|

NO8020

|

|

SA192

|

SA213-T22

|

SA333-Gr.7

|

SA269

|

TP316LN

|

A789-S32760

|

SB111-C68700

|

SB338-GR.7

|

SB514

|

NO6022

|

|

SA209-T1

|

SA213-T5

|

SA333-Gr.8

|

SA376

|

TP321

|

A789-S32707

|

SB111-C44300

|

SB338-GR.9

|

SB619

|

N10276

|

|

SA209-T1a

|

SA213-T9

|

SA334-Gr.1

|

TP304

|

TP321H

|

A789-S32304

|

|

SB338-GR.12

|

SB622

|

NO4400

|

|

SA209-T1b

|

SA213-T91

|

SA334-Gr.3

|

TP304L

|

TP347

|

A789-S31500

|

|

|

SB626

|

NO6600

|

|

SA210-A1

|

|

SA334-Gr.6

|

TP304H

|

TP347H

|

S31254

|

|

|

SB674

|

NO6601

|

|

SA210-C

|

|

SA334-Gr.7

|

TP304N

|

TP405

|

254MA

|

|

|

SB677

|

NO6625

|

|

SA214

|

|

SA334-Gr.8

|

TP310H

|

TP409

|

17-4PH

|

|

|

SB704

|

NO690

|

|

SA513 MT 1010

|

|

|

TP310S

|

TP410

|

17-7PH

|

|

|

SB705

|

NO8800

|

|

SA513 MT 1015

|

|

|

TP309S

|

TP430

|

15-7PH

|

|

|

N1001

|

NO8810

|

|

SA513 MT 1020

|

|

|

TP317

|

TP439

|

|

|

|

N10665

|

NO8811

|

|

|

|

|

TP317L

|

TP444

|

|

|

|

N10675

|

NO8825

|

|

|

|

|

TP348

|

TP446

|

|

|

|

TP904L

|

|

|

|

|

|

TP347HFG

|

|

|

|

|

|

|

English

English Español

Español Français

Français بالعربية

بالعربية